The square pieces of smooth, orange, slightly rubbery stuff seemed like the quintessential lunch food, showing up on everything from gooey grilled cheeses to baloney sandwiches.

To the average mid-century housewife, however, the invention of American cheese singles and slices was nothing short of revolutionary!

Because of its unique blend of ingredients and the way it was made, this processed cheese food product stayed soft and fresh for a long, long time and was not prone to mold. (In fact, American cheese will probably dry out around the edges before it ever molds, assuming you haven’t already eaten it long before the expiration date anyway.)

Creamy, smooth and mildly-flavored, American cheese is inoffensive in taste, though not particularly delicious when eaten at room temperature, or cold. It’s never really crossed over to charcuterie, for example, unless it’s for a kid’s snack plate.

But when it’s melty — well, that’s when processed cheese really shines. In fact, no traditional cheese can offer the superior texture of melted American cheese, which is probably why our love affair persists, even as some of us, at least in public, have gotten snobbier about processed cheese.

While today we take the much-maligned processed American cheese products for granted, this collection of vintage advertisements demonstrates just how much of a novelty it was in the mid-20th century.

PS: Don’t miss the ad below from 1965 which thoughtfully included a step-by-step tutorial on how to open the individual slice plastic wrapping on a Kraft American cheese single.

How they made American Cheese: New cheese process revealed by Kraft Foods (1946)

By the Angola Herald (Angola, Indiana) November 1, 1946

Natural American cheese which ages in its own transparent wrapper and combines uniformity of flavor, convenience and economy soon will be available to consumers everywhere,

Thick rinds, flaky paraffin and cheesecloth bandages are eliminated in this new type of American cheese, eliminating also much of the fuss and bother of trimming and handling which is characteristic of the old styles.

Produced in 10-pound units, this new style of cheese is already available in many markets and production is being steadily expanded, according to John H. Kraft. president of the Kraft Foods Company which is making and distributing the product. The company had the cheese ready for distribution in 1941, but wartime demand necessitated holding up production, Mr. Kraft said.

“Development of this size and style of cheese is one of the most important steps into this history of American cheese manufacture,” Mr Kraft declared. “It means the retail grocer will have available to consumers a high-quality natural cheese, made from pasteurized milk, which has practically all the convenience, ease of handling and waste-free characteristics of processed cheese in loaf form.

WHAT’S IN IT? Find out more info here: What is American cheese, really?

Many cheesemaking, packaging and curing problems had to be solved before full production could be started for the ten-pound sizes. The old method of American Cheese production was to make the cheese in sizes ranging up to 80 pounds.

The cheesecloth bandage was applied and the cheese dipped in molten wax. When it reached the consumer, the cheese was cut into irregular-sized shapes slices or chunks, inconvenient to handle both for the retailer and the consumer.

The new product is pressed into its rectangular shape and packed right in the factory, with the bandages and paraffin eliminated. It cures with little or no rind, which means a minimum of trimming when it is sliced for sandwiches, cut for dessert, or placed on a piece of pie.

A number of production units are turning out this cheese in quantity and additional plants are being converted as fast as wrapping and other equipment can be obtained.

American cheese takes a different turn (1976)

By Susan Seliger, The Daily Item (Sunbury, Pennsylvania) January 5, 1976

Cheese is a part of our heritage.

The Bible reports about a delivery of honey and curdled milk to David in 1000 B.C: In Homer’s ”Odyssey”‘ King Menelaus of Sparta praises cheese. And what else was little Miss Muffet doing on her tuffet but eating half-done cheese?

However, cheese today has taken a different turn. It is pasteurized, processed, emulsified, colored, sliced like paper, wrapped in plastic, and set on shelves to last forever.

What are we eating under the name of cheese? What is the difference between natural and process cheese in content, nutrition. price and taste?

ALSO SEE: Remember these vintage Hamburger Helper flavors we thought were so delicious in the 70s, 80s & 90s?

All cheese is basically concentrated, fermented milk. The source of milk usually is the cow, though Italians used to make mozzarella from water buffalo and Roquefort comes from the milk of ewes.

Natural cheese results from concentrating components of milk by removing water. Through the controlled interaction of the curds, heat, bacteria, acids, enzymes, salt and other micro-organism.

Cheese with a variety of characteristics can be produced.

Soft cheeses are simply shaped: hard cheeses are aged under pressure. Blue cheese is made by adding blue mold spores to the milk and piercing the ripening cheese with needles to make air passages in the cheese wheel.

Camembert and brie are infected with white molds spores at the beginning of the curing process. Limburger achieves its peculiar taste and smell from a bacterial smear applied to the rind. And propionic-acid bacteria are added to Swiss for flavor and so that during aging they will release carbon dioxide and create the holes, or eyes, without which a swiss is not a swiss.

ALSO SEE: Vintage Borden’s cheese spreads came in free collectible party glasses & crocks

Each kind of cheese must meet specific fat and moisture content requirements set out by the Department of Agriculture regulations. Cheddar, the most popular American cheese, must contain a minimum of 50 percent fat and a maximum of 90 percent moisture.

Natural cheese also may legally contain the following additives: hydrogen peroxide, which destroys spoilage organisms: benzoyl peroxide, a bleach; sorbic acid, in sliced or cut cheese only to prevent mold growth: green and blue dyes; calcium chloride to firm the curd; artificial smoke; and spice or spice oils. Each must be listed on the label if used. Only artificial coloring can be used without being declared.

Process cheese

Process cheese results after mixing cheese together, adding an emulsifier, and heating until one gets, in the words of the federal regulations, ”a homogenous, plastic mass.” Moisture and fat content must be kept close to the average of the component natural cheeses.

Process cheese was first developed in America in 1916 by J.L. Kraft, a young man who previously had made his living selling natural cheese off a horse-drawn cart. Kraft discovered that by adding an emulsifier, the cheese could be sliced without crumbling, and would melt smoothly instead of becoming tough and stringy as natural cheese often does.

Eventually, Kraft wound up with a solid cheese that was bland in taste, the same every time, easy to use in cooling, and long-lasting.

It was not a big step from Kraft’s findings to what is now called process cheese food. It is even milder than process cheese, and melts even more smoothly. It is lower in fat (no less than 2 percent milk fat) and higher in moisture (no more than 4 percent).

In addition to the ingredients in process cheese, cheese food can contain skim milk, whey, skim-milk cheese, organic acids, meats, vegetables and flavorings.

Cheese spread

Pasteurized process cheese spread is still softer and more spreadable. It contains more moisture than process cheese (up 44 percent) and less fat (a minimum of 20 percent). The pasteurized product may contain any of the following: milk-whey solids, sweetening agents, vegetable gums, pimientos, olives, peppers, spices and flavorings.

ALSO SEE: Check out these retro Cheez Whiz recipes from their Idea Book (1974)

There is even such a thing as imitation pasteurized process cheese spread. This classification includes any substance that doesn’t meet the federal standards on butterfat content for cheese spread. It has few calories and must be labeled ”imitation.”

Nutrition

Nutritionally there is little difference between natural and process cheese. They contain nearly the same percentages of water and fat. The secondary heat treatment that process cheese undergoes seems to have little or no effect upon the protein, vitamins or minerals.

Many of the pasteurized process-cheese foods and spreads contain less fat and, therefore, fewer calories. But this possible advantage must be weighed against the effect on the taste.

A matter of taste

But humans do not live by nutrition alone. Taste matters. What do Americans prefer?

According to a demographic and geographic survey conducted in 1972 by the United Dairy Industry Association. Americans consume just under 50 percent more natural than process cheese types. Cheddar leads, followed by Italian varieties and then swiss

But natural cheese’s pre-eminence may be slipping. The trend in the past 20 years, though toward a general increase in cheese consumption, has shown greater increases in the purchase of process cheese (up 34 percent than in natural — up 27 percent).

ALSO SEE: Jeweled cheese ball: Cheddar-brandy flavored appetizer with slivered almonds (1982)

Kraft Cheese – American cheese loaf (1925)

Food for thought.

A food for protein; a food for mineral salt, for calcium and phosphorous; all the essential food elements for sturdy child growth are to be found in good cheese. And every essential element of good cheese is always found in Kraft Cheese.

Kraft De Luxe Cheese Slices (1958)

They’re called Kraft De Luxe Slices because they have really rich cheese flavor!

Why do Kraft De Luxe Slices taste so much better than others you may find in the grocer’s dairy case?

It’s simple. Kraft cheesemakers are very fussy about the natural cheeses from which they make these handy pasteurized process cheese slices.

For example, it takes fine natural cheddar cheese to give such flavor as you get in Old English Brand. And only truly nut-sweet natural Swiss can make the Kraft De Luxe Swiss slices so good!

That’s why they are called Kraft De Luxe Slices. That’s why your cheese sandwiches taste so extra good when you use the handy slices marked Kraft.

Try them all — the Kraft American, Kraft Pimento, Old English Brand, Kraft Swiss, Kraft Brick, and Kraft Muenster.

The various 1960s Kraft cheeses (1965)

Many folks tell us they love Kraft cheeses… always pick ’em by brand name, even if sometimes they cost a few pennies more. Frankly, there are many ways we could cut costs.

But if we did, we would be tampering with the quality, the flavor and the nutrition of our cheese… the very things you rely on when you use Kraft cheese products. No, we can never cut quality. Too many people depend on us for that. For good food and good food ideas… Kraft.

Shown: Philadelphia Cream Cheese, American Slices, Cheez Whiz, Natural Swiss Cheese

ALSO SEE: 26 ways to serve an old favorite: Hot dogs

How to open Kraft Singles cheese squares (1965)

For you! Just to discover the ease of Kraft “Singles”.

- Flip open one side of the transparent envelope.

- Flip open the other side that wraps the single slice.

- Flip!… and your individual slice is on a great cheese sandwich.

No re-wrap job. Each of the sixteen slices is ready-wrapped. No dried edges ever! Kraft American Singles — The best-tasting pasteurized process American cheese food you can buy.

ALSO SEE: 10 old-fashioned macaroni and cheese recipes

Lunch for a bunch: Treatwich-in-the-round (1966)

It’s a treatwich-in-the-round topped with the best-tasting pasteurized process cheese slices you can buy: the ones marked Kraft.

Top a big, toasted round of rye bread, Kraft mustard-spread, with hot corned beef hash (to which you’ve added chopped pimiento and green pepper). Then, plenty of that mellow Kraft American with extra rich cheese flavor in every bite. Broil a bit, and cut in wedges for the gang.

Popular Kraft American comes in big packs as well as the 8-slice size; also get sharp Old English brand, Kraft Swiss, Brick, Muenster.

ALSO SEE: 20 frosted party sandwich loaf recipes to make… or avoid

Make a golden grilled cheese sandwich (1967)

It’s an autumn tradition, this golden grilled sandwich. A slice of warm, home-baked bread, stacked with juicy tomato, rippled bacon… and mellow Kraft American cheese.

Kraft Sandwich Shop (1974)

We’ve harvested some of the best sandwiches around, to start off the fall season. They’re all made with Kraft Singles process cheese food slices and Kraft Natural Slices, for the big flavor that hearty fall recipes love.

Kraft Singles American cheese slices for sandwiches (1970)

Because a sandwich is versatile, it can do many things. With cheese it is colorful, flavorful, exciting. With Kraft American Singles it’s nutritious and easy. It can be a full meal or a love snack. It can be a lot of fun. Here’s how.

1. The first rule in sandwich making is — if you like it, include it. Included in this sandwich is everything a boy likes — hot dog, coleslaw and an American Single.

2. Use a cookie cutter to make unusually-shaped white bread sandwiches — star, heart or animal-shaped.

3. Instead of the usual three meals a day, why not give your shut-in five or six to break the monotony. For in-between meals, a sandwich made with American Singles pasteurized process cheese food is perfect. Those individually-wrapped slices are easy to use — even six times a day — because there’s no rewrapping. For added variety, they come in Swiss, Pimento and Salami flavors, too.

ALSO SEE: Remember Hickory Farms? That’s how we fed our charcuterie obsession back in the day (1970s-90s)

4. Cover a checkerboard with plastic wrap and use it as a tray for lunch.

5. Serve cheeseburgers with a happy face — pimento strip for the mouth, sliced olives for the eyes.

6. Indoor cookouts are fun for everybody. Wrap a cold cuts and Singles sandwich in foil, heat it, then serve it hot and melty right in the foil. Remember that Singles melt faster than other slices, so the sandwich is quite a quickie!

7. Serve lunch in a lunch box or wrapped in a knapsack.

8. Try a pizza sandwich a quick treat. Split an English muffin and spread with catsup, sprinkle with oregano, and top with an American Single. Slide it under the broiler until the cheese food melts.

9. At each meal slip something into the napkin — a get well card , a dime, a little toy or a comic book.

Mcdonald’s hamburger with American cheese slice (1978)

100%. Pure beef. Pure pleasure.

That’s what you get in every Quarter Pounder with cheese sandwich. A lean and unmistakably good taste of 100% pure, domestic beef including cuts of chuck, round, and sirloin. No fillers. No additives. Simply pure lean beef, leaner than the ground beef most people buy.

And for cheese lovers, there’s not one, but two melted slices of our rich and golden cheese. All tucked into a freshly toasted, sesame seed bun. It’s your Quarter Pounder with cheese. And we make it 100% for you.

ALSO SEE: Vintage McDonald’s: See 5 decades of the famous fast food chain’s retro restaurants, menus & history

Sandwich Days with Kraft, Doritos, Miracle Whip and more (1978)

Cash in on some of your summertime favorites…

Pepperidge Farm Wheat Bread, “Bread like it used to be.”

Miracle Whip Salad Dressing, “The Bread Spread”

Oscar Mayer Cold Cuts, “In 37 different varieties.”

Kraft Singles Process Cheese Food. “America’s Favorite American.”

Hawaiian Punch drink mix (Pre-Sweetened and new Unsweetened), “The-One-of-a-Kind-Taste.”

Nacho Cheese Flavor Doritos brand Tortilla Chips, “Taste as good as they crunch.”

MORE: Holiday appetizer recipes from the ’60s: Saucy cocktail meatballs, Cheese trees & Wreath rollups

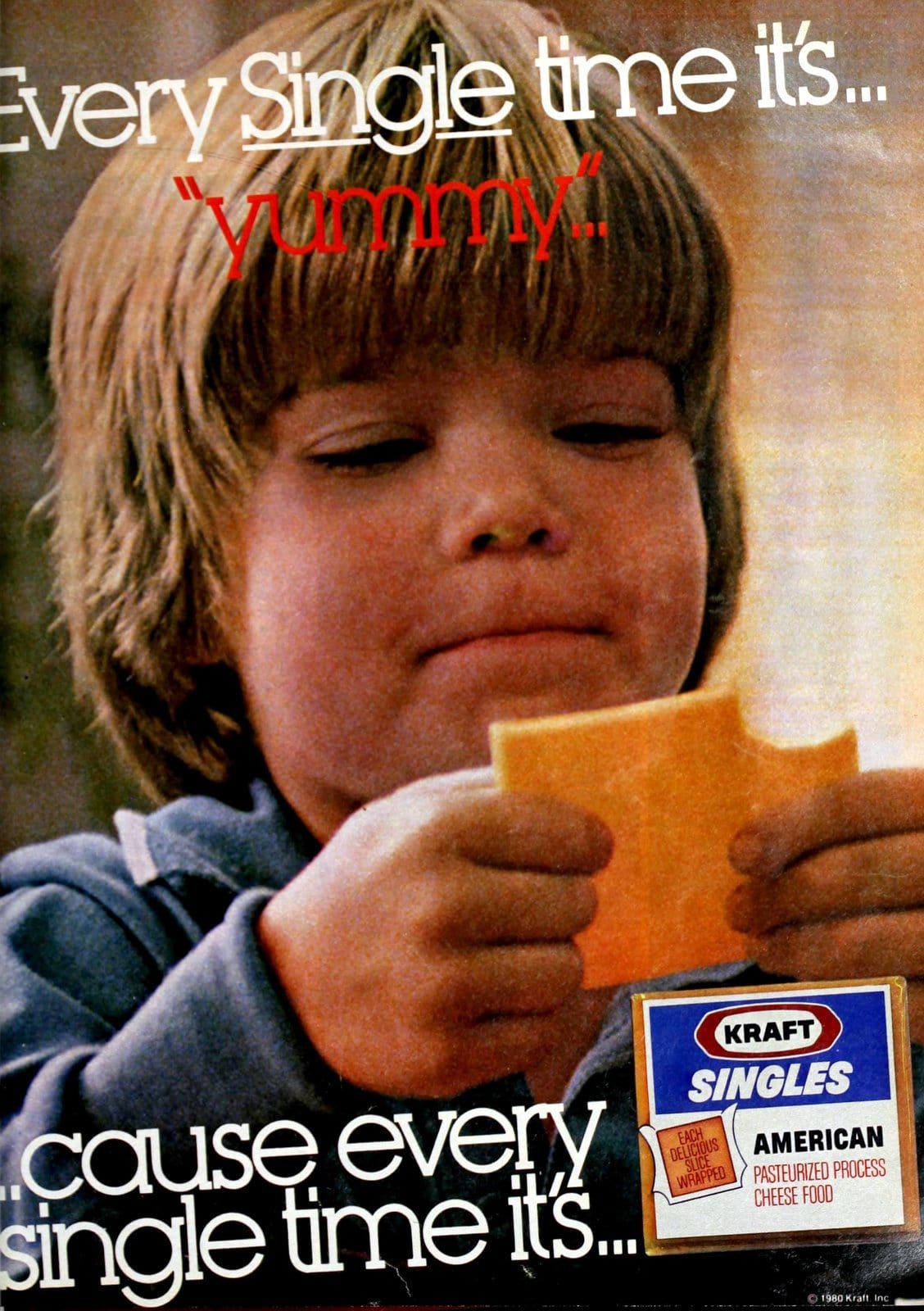

Kraft Singles American cheese slices (1980)

Kraft American cheese Light n Lively singles (1980)

Believe it! Light n’ Lively process cheese product has a touch of cream — and still only half the fat.

So enjoy its all-American cheese flavor on salads. sandwiches, or for snacking. Try Light n’ Lively process cheese product from Kraft, and taste the difference a little cream makes.

NOW SEE THIS: What is American cheese, really?